Our Educational Primer Series presents a deep dive into the technical elements that bring together the world of 4D Systems and what we have to offer. You’ll find that this information series, developed with our experts and engineers, is the perfect place to power up your knowledge and take your understanding of our hardware and software to the next level. As always, feel free to reach out and get in touch. The best learning is interactive and we’d love to hear from you.

File Downloads

The benefits of resistive touchscreens

Touchscreens have become an integral part of our lives. We use touchscreens when we type out a text message on our smartphones, when we scroll through a selection menu at a restaurant, when we need to get cash out from an ATM and when we’re using an elevator in a shopping mall. As technology begins to advance and become more and more interactive, touchscreens are bound to be found everywhere – from personal gadgets like tablets, laptops, printers and gaming consoles, to household appliances like cooktops and washing machines, and to public conveniences like car GPS systems, elevators and ticket vending machines to name a few.

In all these touchscreens, you must have noticed a difference between the texture of the touch panels, the response time, and the required pressure you need to apply with your fingers. This is because the underlying technology is different in different touchscreens. Based on the types of touch sensors used in the development of a touchscreen, there are a few types of touchscreens.

Resistive touch

Resistive touch is one of the most commonly used touchscreen technologies and was once the most prevailing type of touchscreen interfaces. It was the American inventor Dr. Samuel G. Hurst who founded the first resistive touchscreen in 1971. He called the sensor Elograph, after his company Elographics and he even received a US patent for his invention in 1975.

Let’s find out more about resistive touch, as well as the benefits of resistive touch.

What is resistive touch?

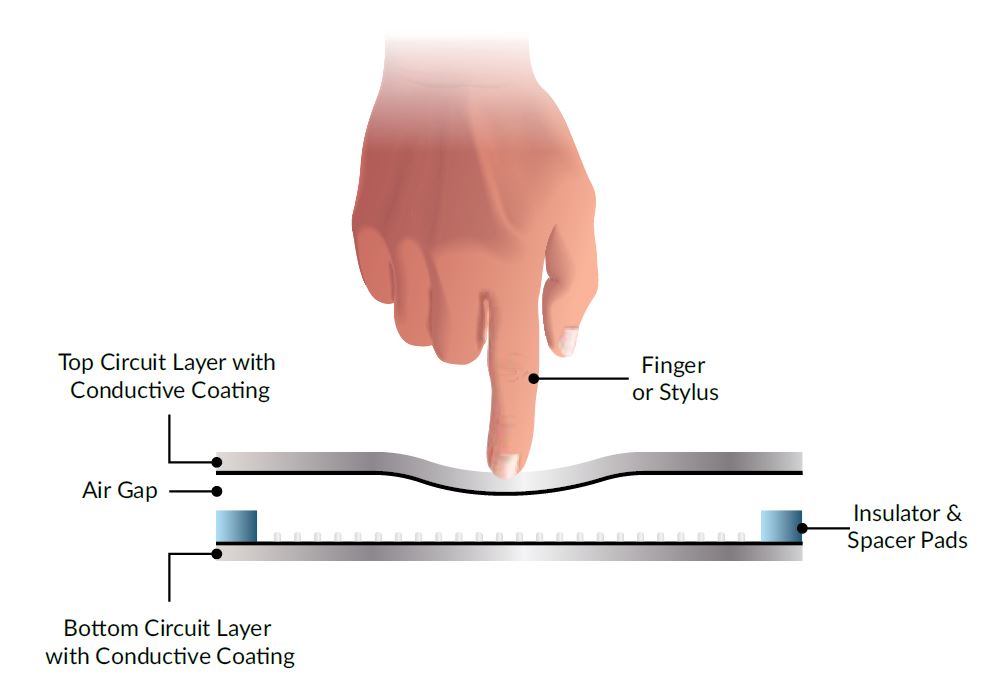

As the name suggests, resistive touch works on the basis of a pressure applied to the screen. A resistive touchscreen consists of several thin layers. The layers comprise of a bottom glass panel that is followed by two resistive circuit layers which are coated with electrically conductive thin metallic layers separated by a slim gap consisting of separator dots.

When pressure is applied on the screen with a finger or stylus, the outer resistive layer is pushed onto the inner layer. The two metallic conductive layers come into contact closing a circuit, causing a current loop and generating a change in resistance on both vertical and horizontal axis. The change is detected by the sensors located on the screen’s edges which in turn find out the exact location by using the horizontal-vertical axis coordinates to indicate the touch point.

Benefits of resistive touch

Let’s take a look at the benefits of resistive touchscreens and how they can be suited to a variety of applications.

Resistive touchscreens are less complex to make due to its simple structure and cost less when compared

to other touch technologies. The affordability of the resistive touchscreen explains their success in highuse

applications like PDAs and Internet appliances.

Resistive touchscreens have more sensors per inch than a capacitive touchscreen; the touchscreens can be touched to perform the desired action using a bare finger, gloved finger and stylus. This property makes resistive touchscreens the preferred choice in an industrial setting, where operators have to use gloves on the resistive touch panel. On the contrary, most of the capacitive touch screens will not work with gloves since the screen actually detects the electrical properties of the finger.

Resistive touchscreens are extremely durable and can be used in tough and harsh environments. The surface is resistant to liquids like water, oil and grease and other contaminants like dust and moisture.

Resistive touchscreens do not use much power.

Resistive touchscreens are very suitable for handwriting recognition. The touchscreen can come with a

built-in handwriting recognition capability.

Though a high degree of sensitivity can be a good feature for a touchscreen, it is not always an advantage in industrial environments. Resistive touchscreens do not respond to stray stimuli such as liquid spills and spatters that are common in an industrial unit that can cause the terminal to react unintentionally.

| Resistive touchscreen devices can have a resolution of 4096 x 4096 DPI or higher. This high resolution makes them ideal for watching movies and playing games. Furthermore, it also supports accurate touch control. |

Most touchscreen technologies use glass plates as the outer touch layer. This is usually not allowed in the

food and beverage facilities as they have strict ‘no exposed glass’ policies. Resistive screens use a tough

polycarbonate outer layer that can contain the glass, even if the sensor screen is shattered by impact.

Resistive touchscreens have been widely used for many years and hope to remain a popular, well-proven and trusted solution in the future as well.

For a great range of LCD screens, visit: www.4dsystems.com.au/products/

Table of contents

Subscribe to our newsletter

Latest Case Studies

This case study unveils a practical application of embedded innovation, highlighting the process and outcomes of upgrading legacy systems in a technology-focused product line. Through strategic technological integration, the project not only uplifted product performance but also markedly improved customer satisfaction levels. The subsequent pages delve into various strategic and operational enhancements made, providing readers with a nuanced understanding of the concrete impacts and subtleties involved in a real-world, engineer-led embedded innovation initiative. A testament to blending traditional systems with modern innovation.

Duratec, specializing in liquid handling devices for various industries, aimed to simplify the control interfaces of their new product line. Partnering with 4D Systems, they integrated a touch display module enhancing user-centricity and operational efficiency. This transition replaced outdated control panels with an intuitive, modern interface without compromising on control capabilities via the RS232 interface. Three new devices were launched, improving user interactions through user-friendly touch displays, showcasing Duratec's commitment to innovation. This collaboration allowed for more straightforward control, monitoring, and interaction with Duratec's devices, ensuring a better user experience and meeting industry demands.

In the challenging process of creating an advanced 3D printer, BCN3D encountered an unexpected difficulty: finding an appropriate, user-friendly display module. Despite initial struggles, BCN3D discovered the solution in 4D Systems’ gen4 display modules. These modules offered superior resolution, processing power, and flexibility. Key to BCN3D's decision was the modules' easy integration via a serial connection and the Arduino-compatible library into their firmware. For its Sigma R17 3D printer, BCN3D upgraded to the gen4-ULCD-35DCT-CLB, a 3.5-inch Intelligent TFT-LCD display module with capacitive touch, further enhancing the user experience. The gen4 series of intelligent display modules perfectly matched BCN3D's requirements, offering innovative solutions in the sophisticated 3D printing space.