Most technology businesses will, at some stage, consider whether it is more efficient to build their own intelligent display solution from scratch or buy an off-the-shelf module. This white paper dives into the key factors that designers and manufacturers should take into account when making this crucial decision. From production and development cycles to the versatility and customisation of the end product, we’ll help you weigh the pros and cons of both options so you can make a decision that best fits your business needs.

In this white paper, we will cover off on:

- Considerations in the make vs buy decision

- Comparison of a modular solution vs a discrete design

- Discrete design implementation

- Modular design implementation

- Example cost analysis: Discrete vs. modular design

- Introduction to 4D gen4 HMI

- Overview of IDE and GUI.

- Examples of successful applications

- Building automation

- Medical ventilator

- Conclusion.

Background

One consistent design trend in recent years has been the increased use of Full Colour Touch Interfaces. These colorful, easy-to-use products combine input/output technologies such as traditional screen technologies, buttons and rotary switches into a single unit. Everybody is familiar with smartphones and tablets, but touchscreen applications also include other consumer devices such as coffee machines and kitchen appliances as well as commercial and industrial machines including drink dispensers, medical diagnostic equipment, machine tools and more.

Considerations in the make vs buy decision

Choosing the right LCD solution for a product can be difficult. For the embedded designer, incorporating an LCD can be as demanding as the rest of the design. There are many things to consider when making the initial decisions. The two most important considerations: design in a discrete LCM and develop all required libraries and software to drive the display (discrete design), or use an off-the-shelf intelligent display module (IDM) that is virtually ready to run out of the box (modular solution). When deciding whether to buy an off-the-shelf module or design a discrete solution in-house, the designer must evaluate development cost, bill-of-materials (BOM) cost, design flexibility, scalability, development time and available design expertise.

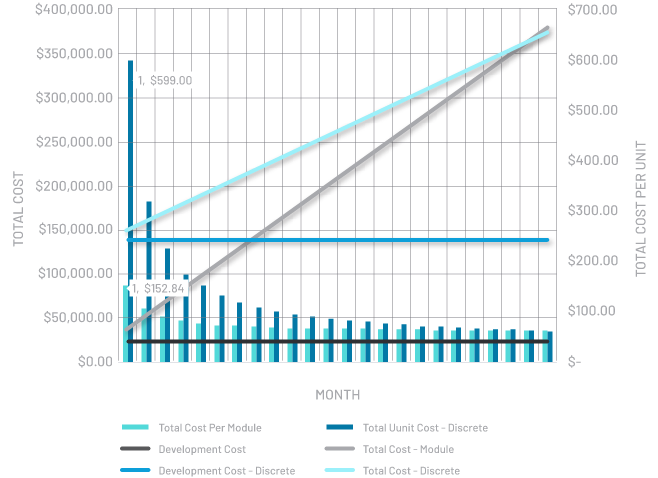

Example cost analysis

In this simplified calculation we compare the costs of the two approaches for a typical application: adding a 4.3 in LCD with capacitive touch to an existing design. Click through to the full white paper for details.

Curious to learn more about what designers and manufacturers need to consider when making this critical decision?

Read the full White Paper

Subscribe to our newsletter

Latest White Papers

Choosing the HMI (Human-Machine Interface) components that your users interact with is a key part of the product development process. But deciding how to produce your intelligent display, which display to buy, to what degree you customize it – and even considering building one from scratch – can be a tough commercial choice. In this whitepaper we provide a comprehensive overview of key commercial factors to consider when evaluating these options.

Touchscreens, accelerated by health concerns like COVID-19, have replaced traditional controls, merging functionality with practicality. 4D Systems leads this transition with aesthetically pleasing display modules enhancing user experience. Partnering with Henlo & Co, a South African premium espresso machine maker, 4D Systems integrated their gen4 modules, improving brewing through data analytics, consistent execution, and precise ingredient measurement. This collaboration showcases the display solutions' potential in elevating operational efficiency and user-centricity in modern appliances.

Intelligent display solutions are the crucial link between automated data and personalised micro-environments. These solutions are the cornerstone of smart homes, controlling everything from lighting and temperature to security and entertainment. Cutting-edge technology seamlessly integrates the physical world with the digital realm. Let’s explore the fascinating world of display solutions and the role they play in shaping our connected future.