Educational Primer Series: Benefits of a Cover Lens Bezel

Our Educational Primer Series presents a deep dive into the technical elements that bring together the world of 4D Systems and what we have to offer. You’ll find that this information series, developed with our experts and engineers, is the perfect place to power up your knowledge and take your understanding of our hardware and software to the next level. As always, feel free to reach out and get in touch. The best learning is interactive and we’d love to hear from you.

File Downloads

Cover Lens Bezel: What is it And Why Do You Need it?

Bezel used to be a term usually associated with the jewellery industry. There, the word is used to describe a groove that holds a gemstone or a watch crystal in its place. However, soon the word gained popularity, and it was widely used to describe other things too – such as the rim around gauges like the speedometer in a vehicle.

It did not take long for the word to enter the technology industry as well – the bezel is now a familiar term in the computer industry too. Here, it is used to refer the edge around the monitor or the front of a desktop case. And as mobile phones and other handheld devices gained popularity, bezel became a buzzword in the mobile industry as well. In the mobile industry, the term refers to the area of display surrounding the screen.

Bezel in the modern industries

A screen bezel is the area display surrounding the screen of your gadget – mobile, TV, tablet phone, touchscreen security systems and more. The bezel can be either plastic or metal. In simple words, the bezel is the border between the gadget’s display area and its frame. Although most of the earlier gadgets featured boarder bezel, most of the latest gadgets come with ultra narrow bezels. In many cases, they are so narrow that one feels the device doesn’t have one at all. A thinner bezel means more screen display area and vice versa.

Cover Lens Bezel

As technology evolved, most gadgets started offering more functions than they originally offered. For instance, mobile is no longer a simple tool to make and receive calls, but a device to send and receive emails, a camera, a news portal, handheld TV and more. Most other gadgets are now all in one tool offering a wide range of uses. As such, they have become more sophisticated across the globe.

It is not surprising then that bezel has made its presence known among these gadgets too. A cover lens bezel is basically a cosmetic feature adding to the aesthetics of the device and its screen. However, that doesn’t mean it is without any practical use.

Here are some of the benefits of the bezel:

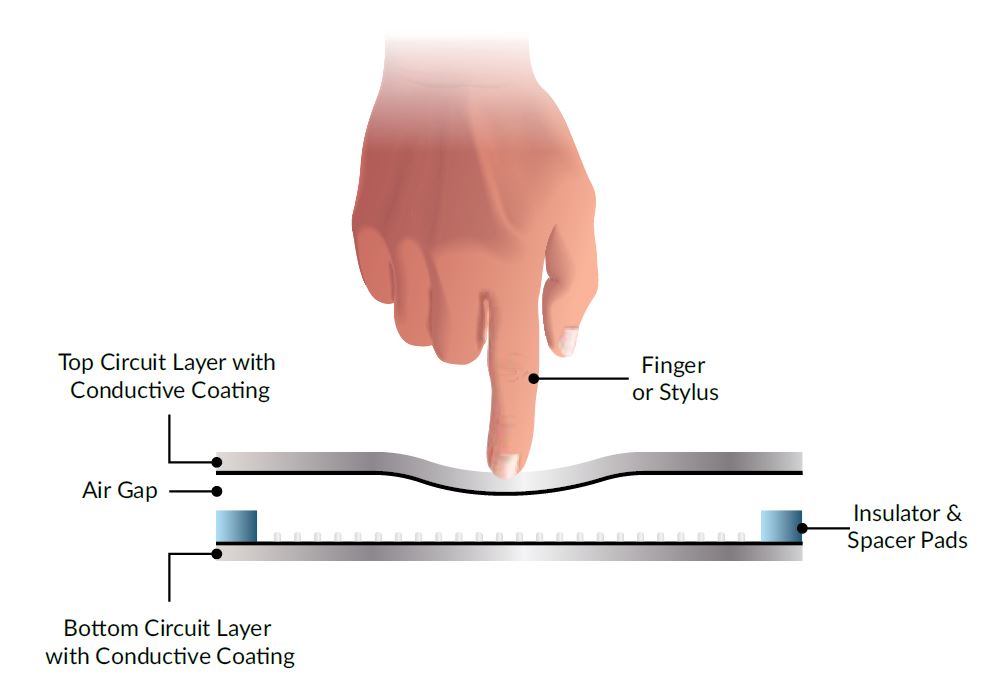

One of the major benefits of the bezel is it provides additional protection to the system. Although most people take good care of their devices, they are likely to scratch or damage the screen in one way or the other. Sometimes, a drop could mean broken screens, rendering the device useless, especially if it is a touchscreen. A cover lens bezel can act as a safeguard against scratches and other pollutants like dirt, among others.

Lens covers are easy to replace than the actual screens themselves. Additionally, you can change them from time to time if you need a new look or better technology.

Although some people might think the lens cover bezel does not add any value to the devices that is not true. Well-fitted into the frame of the device, a bezel could save it from popping out of its place in case of a fall or other such impact. However, when you have a bezel around it, it would mean the screen is firmly held in its place even in the event of a fall.

A bezel improves the aesthetics of the device itself. If you are someone who loves add-ons, a lens cover bezel can be your best friend. It can be used to improve the overall look and feel of the system.

A bezel adds to the usability of the device because in its absence you are likely to activate a function on the screen accidentally.

Here are some of the benefits of the bezel:

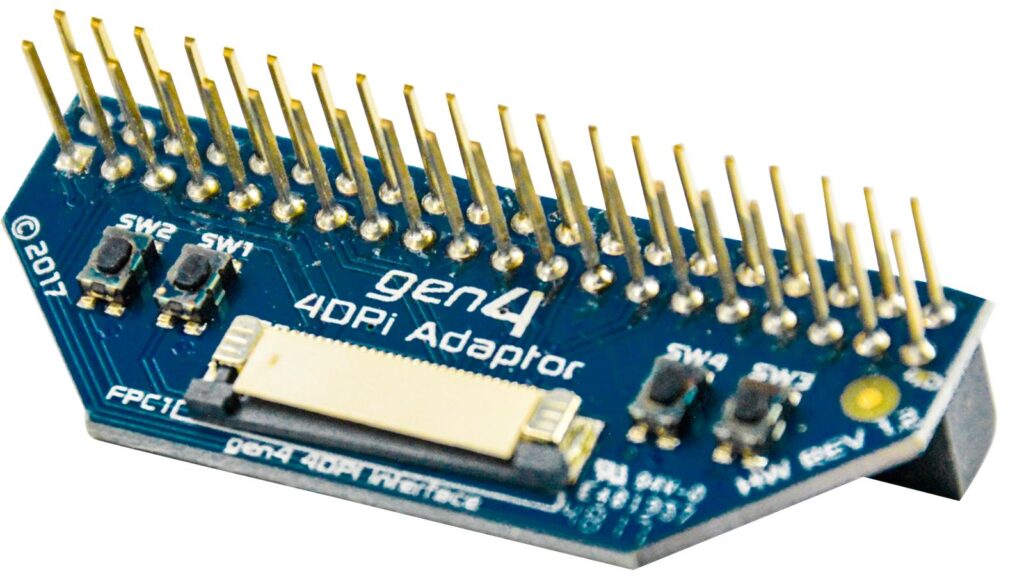

4D systems offer state of the art intelligent display solutions covering a vast range of requirements. Whether it is smart LCD modules or TFT modules, we offer solutions to suit the needs of our users. All the gen4 display modules with resistive touch features come with bezels. These bezels not only offer a sleek cover to these display modules but also provide an easy way to mount the display modules into the enclosure. The display module is mounted on the bezel which provides a mounting solution into a panel while keeping everything firmly together.

For a great range of intelligent displays, visit: www.4dsystems.com.au/products/