Historic Hotel in Fort Worth Texas Digitally Transformed with Smart Display Solutions from Australia

‘The Sinclair’ Hotel undergoes a stunning digital transformation and retrofitting of their Building Automation System.

In Fort Worth Texas, stands an early 1900s building.

The original elevator doors and cigar boxes might fool one to think they have travelled back in time. It is anything but: from check-in to accessing your room, the hotel is futuristic and all digital.

Image: The Sinclair, Fort Worth Texas

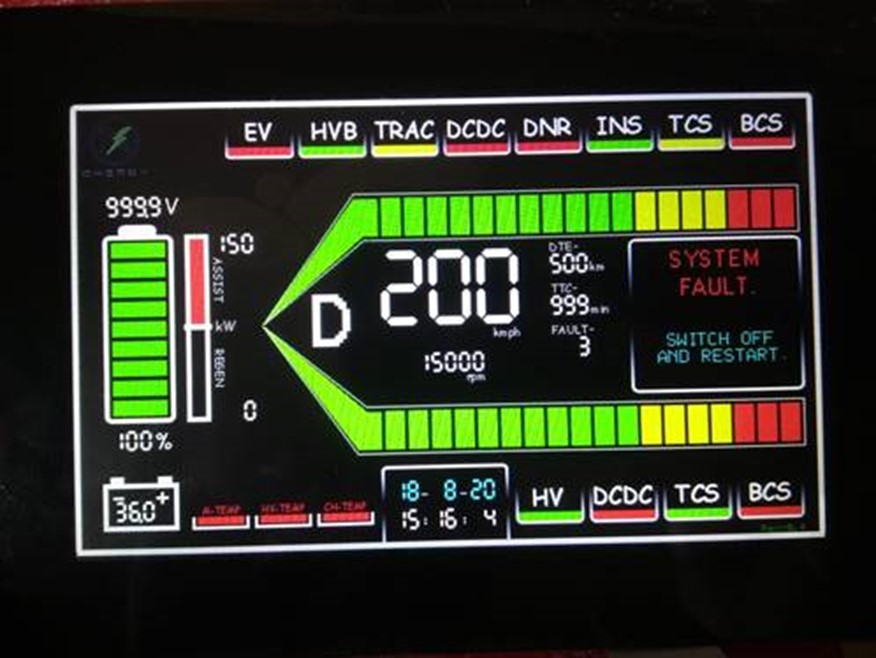

At The Sinclair – and Autograph Collection of hotels – the guest can adjust the temperature of the room, the light settings in the suite’s bedroom and bathroom, the window shades, and even the shower temperature to the exact degree that they choose.

Image: The Sinclair In-Room control interface, created using 4D SYSTEMS’ 4Discovery-50.

Companies like Intel, Cisco, NuLEDs and Igor-Tech have their data and Internet of Things technology weaving everywhere behind the walls of the entire hotel, quietly and seamlessly, helping share and utilise data that drives the digital technology of the world-first all-digital hotel.

The vision of Sinclair hotels to turn a historic building into an upscale hotel of the future came alive as result.

But The Sinclair did not overlook the very humans who would come to enjoy their signature hotel space.

Whilst innovation through data drives the hotel’s digital infrastructure, it is the way humans interact with that data and choose to create the micro-environment most suited to them during their stay is what brings the hotel to life.

And this bridge – between data and the micro-environment- is 4D SYSTEMS display solutions, right at the fingertips of every guest in the same elegant aesthetics as the hotel itself boasts.

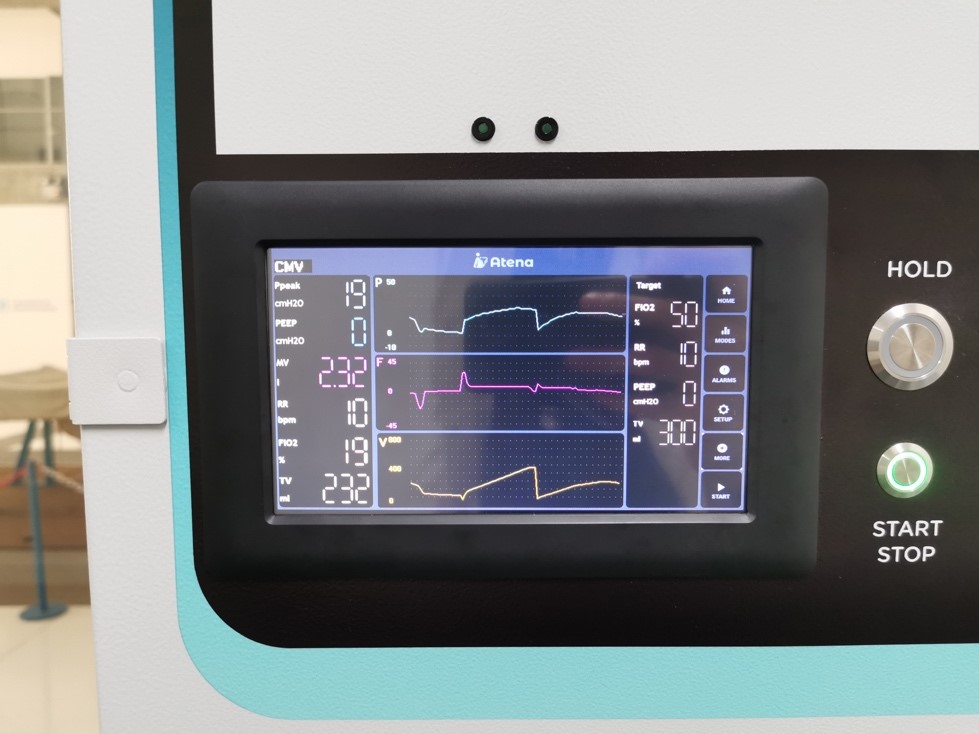

Image: The Sinclair media control interface is available inside the bathroom.

4D SYSTEMS customised its intelligent display module to suit The Sinclair’s specifications, as well as to the project’s partners like Intel, Cisco and Igor-Tech.

At the centre of the guest’s attention is the custom-designed 4Discovery smart display system from 4D Systems, whilst the sophisticated IoT, PoE (power over ethernet) and the entire automated digital infrastructure quietly and invisibly operates efficiently behind the scenes, contributing to immense energy savings for The Sinclair, thus creating a more sustainable and energy-efficient building.

Custom Solutions

4D SYSTEMS can develop custom solutions with you for your building automation project. To discuss solution design or introductory pricing, get in contact with our team via our Contact Sales page.