A Melody of Innovation and Nostalgia: Analog Audio Design’s TP-1000

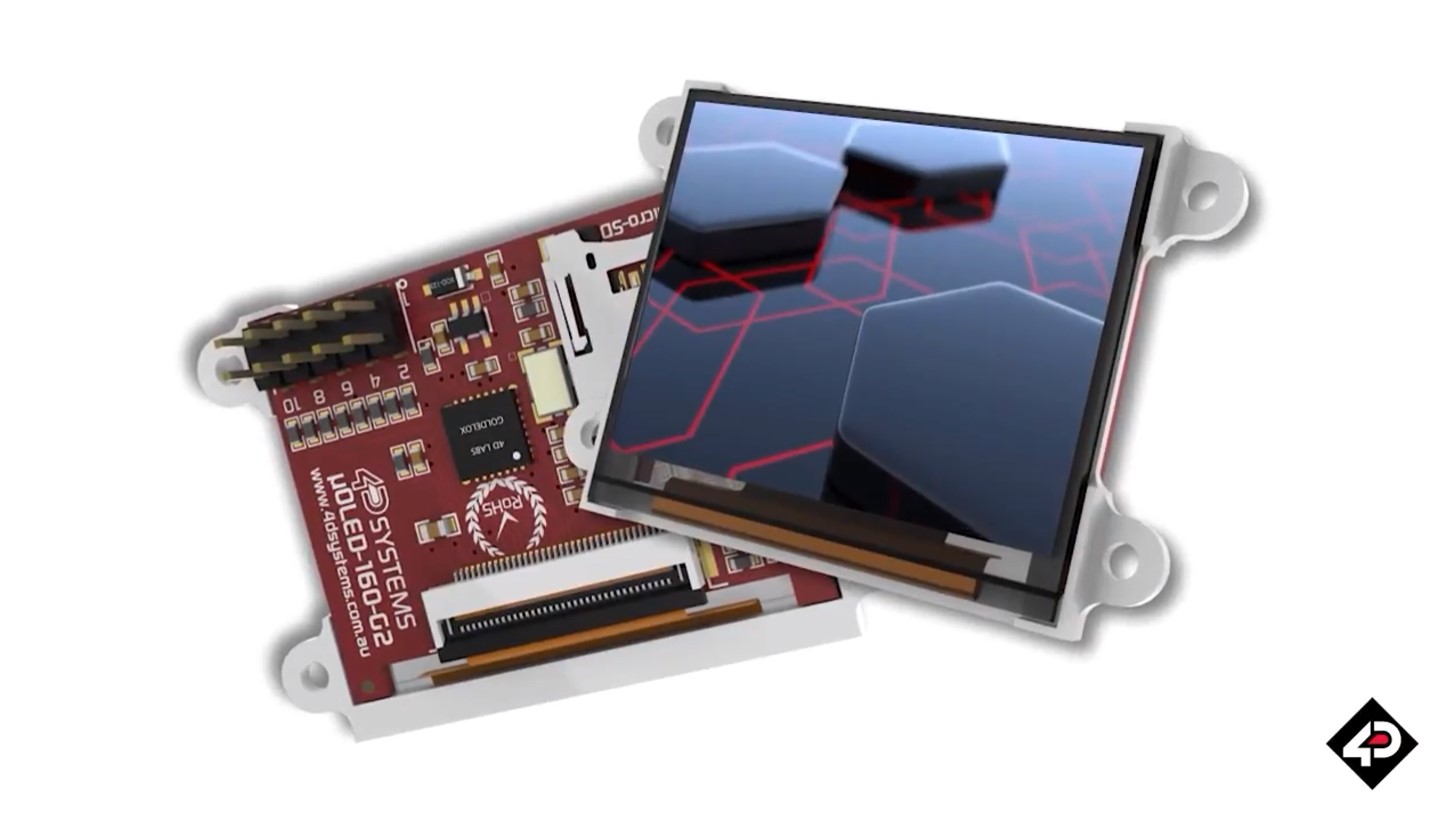

The gen4-uLCD-50DCT-CLB display integrated in the Analog Audio Design’s TP-1000

Once a cornerstone of musical delight, the tape player has long held a place in the hearts of music enthusiasts. Many still believe music on tape offers qualities superior to that in digital format; a warm, rich sound, a wide dynamic range and a more authentic representation of the original sound. For some, the tape player remains a soulful connection to the past.

It’s unexpected, then, that a new analogue tape player would be released against a backdrop of smartphones and wearable IoT. However, Analog Audio Design, a small company based in Pleumeur-Bodou in France, saw an opportunity and embedded modern innovation into a late 1900s relic.

Last year, Christophe Martinez, the founder of Analog Audio Design, released the TP-1000 ⸺ an open reel tape recorder. At first glance, it looks like a nostalgic nod to decades past, but the TP-1000 is a harmonious blend of classic charm and cutting-edge innovation.

Here’s how 4D Systems assisted Analog Audio Design with the development of their modern tape player by providing the perfect LCD display solution.

Beyond Vinyl: Reviving Vintage Sound

The recent re-emergence and popularity of vinyl records and audio cassettes prompted Christophe Martinez to consider a new tape recorder project.

“Since 2014, the return of vinyl hasn’t wavered, with sales still on the rise. Today there’s also talk of the return of the audio cassette. Both technologies are based on analogue sound.The market for magnetic tapes has been growing steadily for several years, but the tape recorders capable of playing this type of tape are ageing, difficult to maintain, demand keeps growing and second-hand prices are skyrocketing.”

Christophe Martinez, the founder of Analog Audio Design

Identifying a gap in the market, Christophe began development of a modern tape recorder in 2017. His goal was to provide music-lovers with an unrivalled sound experience, surpassing even vinyl records.

In 2022, he launched the TP-1000, offering customers a new, reliable machine capable of delivering an unparalleled analogue sound experience. The device is entirely analogue and designed for the reproduction of 1/4″ magnetic tapes.

“TP-1000 customers are passionate audiophiles looking for unrivalled sound, superior to that of vinyl. It’s a worldwide market.”

Christophe Martinez, the founder of Analog Audio Design

Harmonising the User Experience

One of the key challenges in TP-1000’s development was providing users with ergonomic access to advanced functions. Having the perfect display module was pivotal to the project’s success.

Christophe had worked with 4D Systems more than a decade prior and, based on this experience, he reached out for assistance.

The simple serial link between the microcontroller and the screen and the screen-integrated graphics processor resonated with Christophe’s vision for the tape player, and he chose the gen4-uLCD-50DCT-CLB display module with cover lens bezel.

The gen4-uLCD-50DCT-CLB is a powerful 5.0″ Intelligent LCD-TFT display powered by DIABLO16. It features an 800 x 480 resolution, delivering RGB 65K true-to-life colours.

Christophe says the touch screen streamlines the design by removing the need for buttons.

“The advantage of a display is that it eliminates the need to add physical buttons for the functions mentioned above, and in the future, it can also be used to add other functions simply by downloading new firmware.”

Christophe Martinez, the founder of Analog Audio Design

The display has been programmed to showcase time counters, speed and equalisation options, audio output levels, and maintenance pages.

A Classic Symphony with Modern Riffs

After four years of development, the TP-1000 successfully addressed the demand for a high-quality, modern tape recorder for audiophiles worldwide.

The tape player boasts impressive technical features, all conveniently accessible through the display interface (gen4-uLCD-50DCT-CLB), making it exceptionally user-friendly. For example, the REW + Play feature automates the tape rewinding process to the beginning and seamlessly initiates playback. The device calculates the optimal rewind distance based on the remaining tape diameter and core diameter, both adjustable on the intuitive touch screen display.

While being somewhat vintage in appearance, the tape player boasts a range of modern capabilities, including a 6.35mm headphone output and an RJ45 Ethernet socket which allows remote control and software updates.

The final outcome garnered immense praise at its launch listening session at the Acoustic Gallery in Paris, leaving attendees astounded by the depth and quality of sound, precision in tape movement and the feeling of unlimited bandwidth and dynamics.

Encore: Soundscape of the Future

Christophe Martinez has ambitious plans for the future, including the development of the TR-1000 recorder version, which will be an advanced edition of the TP-1000. The gen4-uLCD-50DCT-CLB display will see further use, with plans for a touch-screen remote control in subsequent projects.

Analog Audio Design’s TP-1000, equipped with 4D Systems’ gen4-uLCD-50DCT-CLB display module, has successfully brought the unparalleled sound experience of analogue devices to passionate audiophiles worldwide. The incorporation of the intelligent display has added convenience, functionality, and an elegant design to the TP-1000, making it a remarkable and sought-after open reel tape player.

In an increasingly modern world, the TP-1000 remains an ode to music, a testament to the enduring appeal of analogue sound, and proof that technology and culture can co-exist in harmony.

Until next time.