OLED – Choosing the best display for your application

Display Technologies Demystified: A Guide to Choosing the Best One

In today’s world of technology, displays play a vital role in many applications. From smartphones to medical devices, displays are everywhere. The type of display chosen for an application can significantly impact the user experience, power consumption, and overall device performance.

However, with the plethora of display technologies available today, it can be overwhelming trying to discern the key differences and which display is best for your application or project.

OLED technology is suitable for a wide range of applications due to its unique properties. In this blog, we explore the different types of OLED technology, compare OLED to other display technologies such as QNED and LED, and discuss its applications.

What is OLED?

OLED stands for Organic Light Emitting Diode. An OLED display consists of several layers of organic material sandwiched between two electrodes. When an electric current passes through these layers, it emits light. OLED technology has several unique features, such as high contrast, wide viewing angles, and fast response times. OLED displays can also be made very thin and versatile, which means it is relatively easy to produce flexible and transparent displays.

OLEDs enable emissive displays, meaning each pixel is controlled individually and emits its own light. In comparison, LCDs involve the light coming from a backlighting unit). OLED displays feature great image quality; rich colours, fast motion and high contrast. They are well known for producing “real” blacks, which other displays (such as LCDs) have difficulty replicating due to backlighting.

OLED Display Screens

Similar to other types of displays, OLEDs have the ability to showcase images, text, video, and other content on a screen or panel of varying sizes and resolutions. They can be used in applications ranging from small displays, such as those in wearables, to larger displays, used in TVs.

In recent years, OLED technology gained popularity in the high-end home entertainment market due to its exceptional power and performance. OLED screens are also being used more frequently as performance display tools in various industries, highlighting their versatility and usability.

OLED displays can have a resolution of up to 8K, with a pixel density of up to 1000 pixels per inch (PPI). OLED displays can also be produced on flexible substrates, which makes them suitable for conventional, curved or foldable displays.

There are different types of OLED displays, such as passive matrix OLED (PMOLED) and active matrix OLED (AMOLED). PMOLED displays have lower power consumption and are suitable for small displays, while AMOLED displays have higher resolution and faster response times, making them suitable for larger displays.

OLED vs LED

An older technology, LED displays are still frequently used in many applications, such as outdoor screens, scoreboards, and other informational displays. LED displays use a backlight to illuminate the pixels, while OLED displays emit light directly.

However, OLEDs are demonstrated to be superior to LEDs for a vast majority of use cases. Some of the advantages of OLED over LED displays include:

- Higher contrast – OLEDs can display very deep, rich blacks and tonal shades because they emit no light when instructed to display dark areas, while LCD types including standard LED panels can’t achieve the same contrast ratios, resulting in less deep and crisp blacks due to backlight bleed. OLED displays have a contrast ratio of up to 1,000,000:1, which is much higher than traditional LED displays.

- Richer colours – OLED displays have a colour gamut that covers more than 100% of the DCI-P3 colour space, which is higher than most LED displays.

- Faster response times – OLED displays have better response times than LED/LCD panels, achieving response times in as little as 1 millisecond. This makes OLEDs better at displaying images in rapid motion with less noticeable artifacting, while LEDs struggle due to illuminating multiple pixels behind an LCD layer.

- Wider viewing angles – OLEDs emit light directly to the screen without having to pass through a liquid crystal layer like standard LED displays, which can cause refraction and odd viewing effects from acute angles.

- Better power efficiency – OLEDs only illuminate the necessary pixels, while LED displays require a constant backlight.

- Lifespan – OLED displays have a lifespan of around 100,000 hours, which is significantly longer than traditional LED displays.

ULED vs OLED

ULED stands for Ultra Light Emitting Diode – a term coined by Hisense as part of its marketing strategy. At its foundations, however, ULED is still LED/LCD with more advanced display technology.

OLED remains a superior display choice for several reasons:

- Response time – OLED displays have a response time of 0.1 ms, which makes them excellent for displaying fast-moving content with no noticeable motion blur. ULED displays, on the other hand, have a response time of around 5 ms.

- Viewing angle – OLED displays offer a wide viewing angle of up to 178 degrees, which means the image quality remains consistent from almost any angle. ULED displays, however, can suffer from colour and contrast degradation when viewed from certain angles.

- Colour Gamut – OLED displays can produce a wider colour gamut than ULED displays, covering over 100% of the DCI-P3 colour space. ULED displays can typically cover around 90% of the DCI-P3 colour space.

- Power Consumption – OLED displays are more power-efficient than ULED displays because they only require power for the pixels that are illuminated. ULED displays require constant backlighting, which can lead to higher power consumption.

QNED vs OLED

QNED stands for Quantum Dot NanoCell LE – a display technology developed by LG.

QNED displays use a combination of quantum dots and, again, LED backlighting. QNED displays have a higher peak brightness than OLED displays, however there are several more factors that need to be considered when deciding whether OLED or QNED is the better fit for your project:

- Viewing angle – While OLED displays have a viewing angle of 178 degrees, QNED offers a reduced 160 degree view.

- Response time – OLED displays have better response times than QNED displays. OLED displays have a response time of 0.1 ms, which makes them excellent for displaying fast-moving content with no noticeable motion blur. In comparison, QNED displays have a slower response time.

- Contrast – OLED displays have higher contrast ratios than QNED displays. OLEDs can display very deep, rich blacks and tonal shades because they emit no light when instructed to display dark areas, while QNED panels can’t achieve the same contrast ratios due to their reliance on LED backlighting.

- Power consumption – QNED uses 100 – 400 watts, compared to just 50 – 200 watts by OLEDs. OLED displays are more power-efficient than QNED displays because they only require power for the pixels that are illuminated, while QNED displays require constant backlighting, which can lead to higher power consumption.

- Colour range – The biggest difference between QLED and OLED is independent dimming control. While QNED TVs have dimming zones, they still use dimmable light bulbs. The organic, carbon-based materials of OLEDs can produce a wider array of colours or no colour at all.

OLED applications and use cases

Their slim and flexible design, low power consumption and high visibility make OLED displays the first choice fo a range of use cases and applications, including:

OLED technology has a wide range of applications due to its flexibility, thinness, and high image quality. Here are some examples of use cases and applications for OLED:

- Televisions: OLEDs offer excellent image quality, including deep blacks, vibrant colours, and wide viewing angles. They also have a slim design and can be made in large sizes, making them popular for home entertainment.

- Mobile Devices: OLED displays are used in many high-end smartphones, including Apple’s iPhone and Samsung’s Galaxy series. They offer high resolution, excellent colour accuracy, and low power consumption, which helps to extend battery life.

- Wearables: OLEDs are commonly used in smartwatches and fitness trackers due to their low power consumption, thinness, and flexibility. They can also be used for curved displays, which are growing in popularity.

- Virtual Reality: OLED displays are well-suited for virtual reality headsets because of their high refresh rates, low latency, and ability to display deep blacks, which can enhance the overall immersive experience.

- Automotive: OLEDs are increasingly being used in car dashboards and infotainment systems due to their high brightness, wide viewing angles, and energy efficiency. They can also be curved or flexible, which allows for more creative and customisable designs.

- Lighting: OLEDs can be used for flat panel lighting applications, such as task lighting, ambient lighting, and decorative lighting. They offer a soft, diffused light that can be customised for different colours and brightness levels.

Final thoughts

OLED displays are the definitive choice for a wide range of applications, including consumer electronics, medical equipment, and industrial applications.

With their superior high contrast, unparalleled wide viewing angles, lightning-fast response times, and low power consumption, OLED displays provide the most optimal solution for your display needs. The versatility and rich colour gamut make OLED displays the ideal option for almost every industry and application.

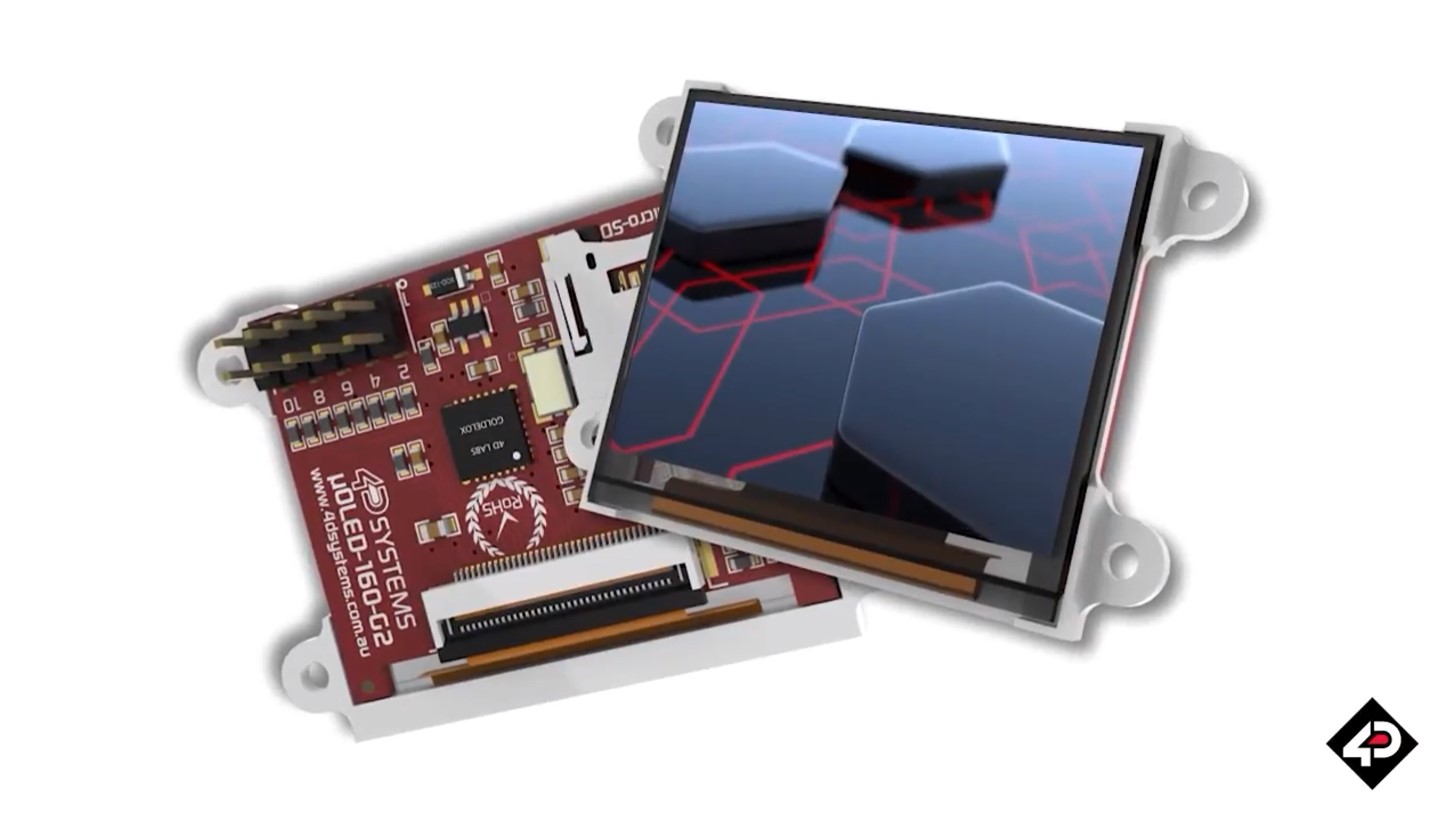

If you need assistance in choosing and integrating the best OLED technology for your project, contact us at 4D Systems, and our team of experts will help you find the perfect OLED display module for your specific requirements.